Sustainability consulting provides tools for Tamturbo's comprehensive business development

Tamturbo wants to be a pioneer in sustainability in its field, which is why the company does close development work with Greenstep's experts.

Tamturbo’s CEO, Igor Nagaev tells about collaboration with Greenstep:

We use a third-party platform for video embedding on our website. To be able to watch video content, you need to accept third-party cookies.

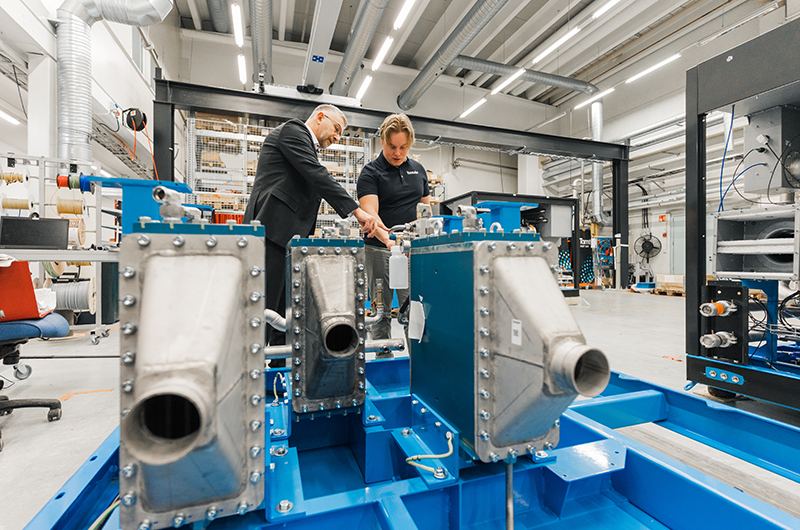

Tamturbo Oyj is a Finnish technology company that manufactures oil-free air compressors for industrial use. The company was established in Tampere back in 2010 with a mission to bring an environmentally friendly alternative to the production of compressed air.

“Sustainability is the core of our business and product design. We cannot continue to waste energy and resources the same way as in the past decades. Our mission is to develop, produce and sell 100% oil-free and sustainable compressors with the lowest total cost. For us, sustainability is the way we design machines and develop our products”, says Tamturbo’s CEO, Igor Nagaev.

Experienced professionals support you on the way to a more responsible business

The multidimensional cooperation between Greenstep and Tamturbo has been ongoing since 2016. During the past few years, Greenstep has supported Tamturbo continuously with HR, payroll, and sustainability services. In addition, the company has also utilized the interim CFO services when needed. Particularly calculating the carbon footprint and assessing the sustainability of operations has been crucial from the perspective of sustainable business.

“We ended up collaborating with Greenstep because we saw them as a comprehensive partner who could also support us in sustainability matters. While discussing with our customers and suppliers about sustainability, we found a challenge in our business. We are a supplier for many production companies that have multiple facilities worldwide. Those companies have targets to reduce their carbon footprint and we were not able to give them answers about our carbon footprint.

It is not easy to find companies that could help you make critical calculations and estimations for your business. We are lucky enough that we can cooperate with Greenstep as they have competence and experience in similar industries”, Nagaev states.

Transparency as a cornerstone of sustainable operations

According to Nagaev, Tamturbo wants to increase transparency towards stakeholders by making accurate calculations of the carbon footprint of the product life cycle. The company aims to have the lowest carbon emissions in the industry and contribute to its customers' carbon footprint reductions.

“The goal of our sustainability project was to have clear and transparent figures, understand what are the contributions of carbon emission in our production and what are the ways to optimize our production. As a result, we know what we could do better and how we could reduce the carbon footprint in our production and products. With the help of figures and calculations made by Greenstep’s experts, we can show our customers concreteness and justify what we are promising. It is very important for us as we are selling machines worldwide”, Nagaev adds.

The development of sustainability utilizes the entire business

Thanks to close cooperation, Tamturbo has gained a clear overall picture of the environmental impacts of production and the structure of the products. Greenstep has helped the company to develop a more responsible and cost-effective way of doing business.

“Working with Greenstep has felt secure as they are professionals in their field. All our possible questions have been answered and they have successfully guided us towards results. Now we understand clearly what ways we have to develop our work and optimize production and product usage. In the future, we will have opportunities to dive deeper into our production and further explore our carbon footprint and how we could reduce emissions. We want sustainability to be included in every phase of the product's life cycle”, Nagaev says.

Published 15.05.2023